Resolution to the Drop: Top Features of a BTU Meter in HVAC Applications

Published on

Choosing the right BTU meter in HVAC requires perspective.

Think beyond your first invoice. This is a generational investment.

The best BTU meters should support your long-term building operations with advanced capabilities that continue to make management of fan coil systems easier and keep maintenance costs low - even 20 years from now.

Let’s break down some of the critical features that set different BTU metering systems apart.

Lead the Future of HVAC Metering

Smart Ultrasonic Thermal Energy Meters are future-proof, built with no moving parts, system agnostic, and come with built-in LoRaWAN-ready communication capabilities, as well as smart alerts.

Discover drop-level accuracy and reliable performance.

BTU Meter Fundamentals — Where to Deploy & What to Expect

It may go without saying, but not all BTU meters, or "thermal energy meters," are created equal.

There are various approaches to basic measurement techniques. Still, other factors come into play, such as how leak alerts are generated, which IoT communication protocols are supported, and the meter's design itself.

Understanding advanced features is important for any buyer during a decision-making process. When you know what’s available, you can confidently weigh opportunity costs and select systems that fit within your strategic goals.

Before we dive into those advanced features, though, we’re going to quickly run down typical applications for BTU Meters in HVAC and the baseline criteria you should expect with a smart thermal meter.

BTU Meters in HVAC Applications

BTU meters can be used to aggregate actionable insights at every layer of a hydronic system, from central plant and building efficiency services to tenant-level billing and renewable energy tracking.

Baseline BTU Meter Criteria for Smart Building Solutions

When choosing a smart thermal energy meter for your application, you should first verify that it meets the required specifications for your system.

Features for Advanced BTU Meters in HVAC

Ultrasonic BTU meters to make your shortlist should offer other advanced capabilities that extend their value beyond data collection.

Meters that offer robust communication options allow you to deploy advanced systems that won’t limit future scaling opportunities or block you into specific software platforms. Other advanced features, like on-device alerting, give you real-time, reliable monitoring insights that reinforce energy management and field operations.

System-Agnostic Meters

Technology is rapidly advancing, and smart building features are becoming increasingly accessible. Your BTU energy meter system should be capable of securely connecting within any network stack and compatible with whatever intelligence tool or efficiency platform you are currently using or may integrate in the future.

Many BTU energy meter brands offer only a narrow range of communication options, or worse, lock them in within proprietary formats.

Prioritize Advanced, Flexible Communications

When a meter’s data is locked behind dual or single protocols, you pay twice. First for custom middleware today, and again for a rip-and-replace tomorrow.

Open-protocol, “heterogeneous” submeters support system-agnostic submetering, allowing you to stream data to any range of applications and move it wherever your teams need it, whether that’s a billing engine, analytics tool, building intelligence data warehouse, or building automation system (BAS).

Securely Stream BTU Meter Data Anywhere with LYNKED

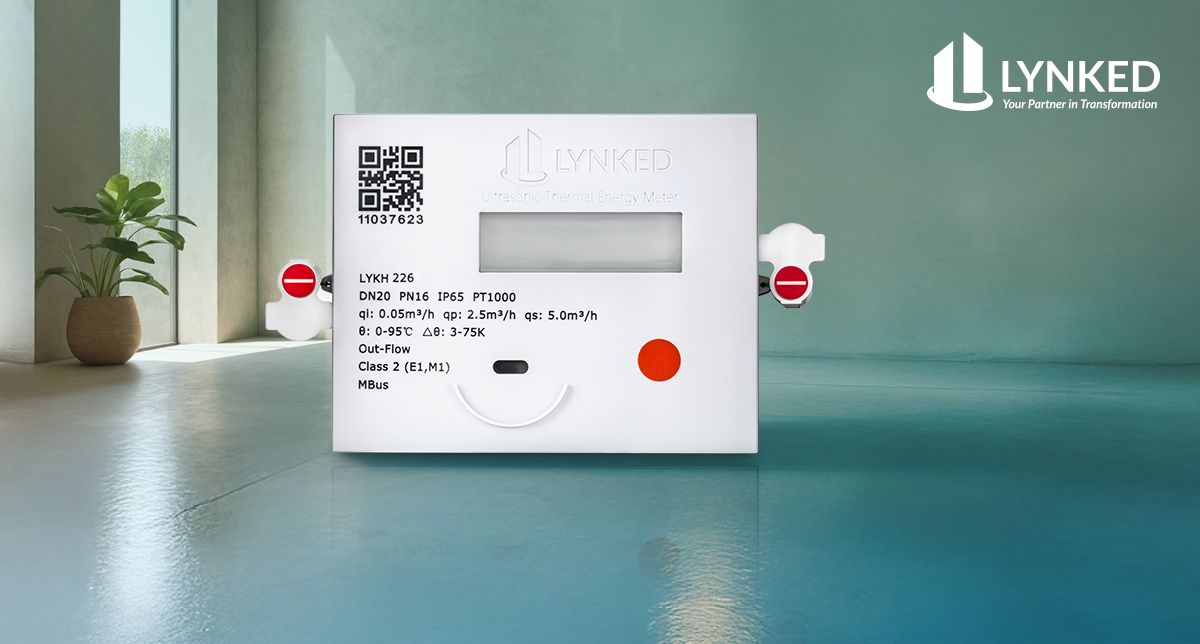

The LYKH series ultrasonic thermal energy meter by LYNKED offers a comprehensive array of major communication types, ensuring broad compatibility and future-proofing.

Beyond the Edge: Built-In BTU Meter Alerting

Advanced BTU meters in HVAC should equip you with live system status and leak detection to monitor, protect, and respond across your entire HVAC loop.

The ability of a BTU energy meter to detect and generate intelligent alerts directly on the device (even beyond the "edge" of the network) is a key advantage, and positions your teams with frontline insights so you don’t have to second-guess notifications.

The Shortfalls of System-Side Alerting

Many boiler and chiller submetering systems rely on centralized algorithms to detect leaks. While leveraging data this way to detect and flag anomalies is impressive, there are still risks of missing critical alerts.

And for drastic events such as a pipe burst or freeze, every second counts.

Power outages, gateway issues, and network disruptions can prevent data from ever being transmitted to a system where it is analyzed and interpreted. A pipe burst could occur, but if relevant data cannot reach a cloud system where it can be analyzed, it goes undetected.

Even a brief blip in connectivity could result in critical event data being delayed or falling completely through the cracks.

Transform Insights with Meter-Based Alerts

Basing alerting systems within the BTU energy meters themselves takes the “brains” behind a system-side algorithm and lets it work directly with a meter’s physics.

When alerts originate from the meter, the meter is analyzing the data, recognizes and identifies an anomaly, and logs the alert. Even if a transmission is missed, the event has already been detected and will be delivered once the connection is restored.

LYNKED BTU Meters: The Ultimate Package

The LYKH Series BTU Meter by LYNKED is an amalgamation of the most advanced features currently available for thermal energy meters.

Ultrasonic sensors on the LYKH Series give systems resolution to the drop, precision meter-based alerting and heterogeneous communication protocols, making it the “ultimate package” for BTU Meters in HVAC for hydronic systems.

- Design optimizes ease of installation with maintenance-free service life.

- Meets or exceeds MID EN1434 and ASTM E3137 / E3137M-17 accuracy requirements.

- Built-in alerting for reliable pre-tagged events (Burst, Leaks, Frozen Pipe, Reverse Flow)

- Flexible Communications (Lynked RF, LoRaWAN, M-Bus, NB-IoT, RS-485, Pulse)

-image.png)